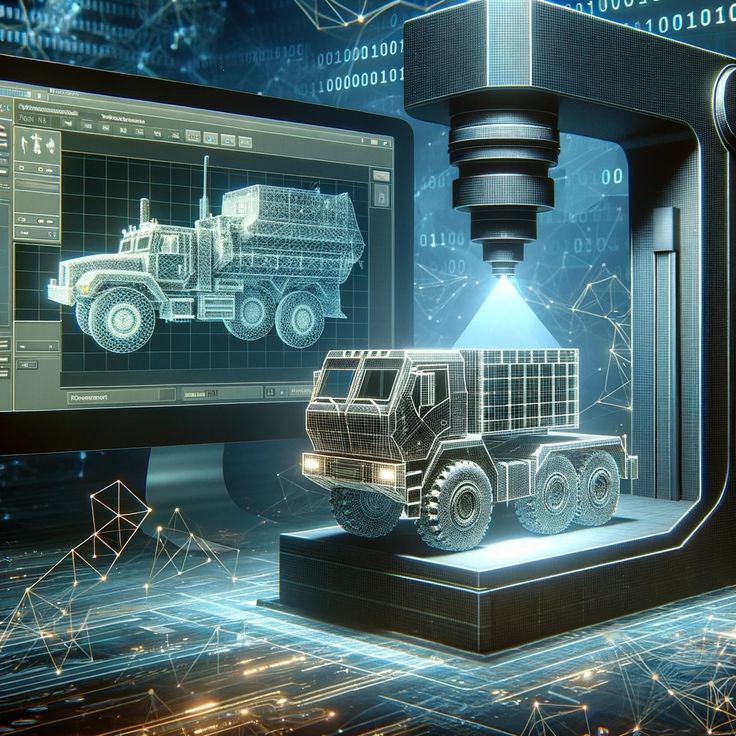

3D Printing (Additive Manufacturing): Shaping the Future of Manufacturing and Design in 2025

In 2025, 3D printing, also known as additive manufacturing, continues to revolutionize industries by enabling the creation of complex objects layer by layer from digital models. This innovative technology has rapidly moved from a niche technique to a mainstream manufacturing process, transforming sectors such as aerospace, healthcare, automotive, and fashion. By offering increased precision, reduced material waste, and the ability to create customized products at scale, 3D printing is pushing the boundaries of what is possible in design, production, and manufacturing.

This article explores the latest developments in 3D printing and its role in reshaping industries in 2025, offering insights into the cutting-edge technologies, applications, and potential benefits of this transformative process.

What is 3D Printing (Additive Manufacturing)?

3D printing, or additive manufacturing, refers to a process where objects are created layer by layer from a digital design file. Unlike traditional subtractive manufacturing methods (which involve cutting away material from a solid block), additive manufacturing adds material only where needed, allowing for more efficient use of resources and the creation of complex geometries that would be impossible with conventional methods.

3D printing can use a wide variety of materials, including plastics, metals, ceramics, biomaterials, and even concrete. The flexibility in materials and design opens up endless possibilities for creating products across a range of industries.

Key Innovations in 2025

In 2025, 3D printing technology has evolved rapidly, with major advancements that are unlocking new applications and pushing the boundaries of manufacturing. Some of the most exciting innovations in 3D printing include:

1. Multi-Material

Multi-material 3D printing allows printers to use two or more materials in a single print. This development enables the creation of complex objects with varying properties, such as flexible and rigid sections within the same item. Multi-material 3D printing is especially valuable in industries like electronics, automotive, and consumer products, where combining different materials (e.g., metals, plastics, and composites) can enhance performance and functionality.

2. 3D Printing with Metals

Metal 3D printing has become increasingly advanced in 2025, with improvements in direct metal laser sintering (DMLS) and electron beam melting (EBM) technologies. These processes allow for the creation of high-performance metal parts used in industries like aerospace, automotive, and medical devices. Titanium, stainless steel, and aluminum are some of the materials that can now be 3D printed with precision, enabling the production of strong, lightweight, and intricate parts for a variety of applications.

3. Bioprinting and Medical Applications

Bioprinting, or the 3D printing of biological materials such as cells and tissues, is an area of significant progress in 2025. Researchers are making strides in printing human tissues, organs, and even blood vessels, opening the door to new treatments, medical research, and organ transplants. This technology has the potential to revolutionize healthcare by providing personalized, functional tissues for regenerative medicine and surgical applications. Additionally, 3D printed prosthetics are becoming more affordable and customizable, enhancing the lives of individuals with disabilities.

4. 3D Printing in Construction

In 2025, 3D printing is being increasingly used in construction to create homes, buildings, and infrastructure. Large-scale 3D printers are capable of printing entire structures using materials such as concrete, metal, and composites. This technology can significantly reduce construction costs and time, improve design flexibility, and minimize material waste. Companies are experimenting with 3D printed affordable housing and emergency shelters, offering a promising solution for addressing global housing shortages.

5. 3D Printed Food

An exciting development in 3D printing is its application in food production. 3D printers designed for food can create intricate food shapes and structures using ingredients such as chocolate, cheese, dough, and pureed foods. In 2025, 3D printed food is expanding beyond novelty creations and is being used for personalized nutrition, healthier food options, and even space exploration food production. This technology has the potential to reshape the food industry by providing sustainable, customized, and efficient food production methods.

6. AI and Automation

Artificial intelligence (AI) and machine learning are playing an increasingly important role in the optimization of 3D printing processes. In 2025, AI algorithms are being used to improve print quality, speed, and efficiency, while also reducing material waste and energy consumption. Smart printers can analyze real-time data during the printing process to make adjustments on the fly, ensuring the highest precision and quality in finished products. This level of automation is helping to scale up production and meet the demands of industries such as consumer electronics and medical device manufacturing.

Applications in 2025

3D printing is impacting a wide range of industries, providing solutions that improve efficiency, sustainability, and cost-effectiveness. Some of the most prominent applications include:

1. Aerospace and Aviation

In aerospace, 3D printing allows for the creation of lightweight and complex parts for aircraft, reducing fuel consumption and costs. Aerospace giants like NASA and Boeing are leveraging additive manufacturing to produce engine components, turbine blades, and aircraft structures with high precision. 3D printing also enables rapid prototyping of new designs, accelerating the innovation cycle in the aerospace industry.

2. Automotive Industry

The automotive sector is embracing 3D printing for prototype development, custom parts, and vehicle components. BMW, Ford, and other automotive manufacturers are using 3D printing to create lightweight parts, engine components, and tooling. This innovation reduces manufacturing time and costs while also allowing for customization of vehicles based on consumer preferences.

3. Fashion and Wearable Tech

The fashion industry is witnessing a transformation thanks to 3D printing, with designers using the technology to create customized clothing, shoes, and accessories. 3D printed fabrics and wearable tech have made it possible to create designs that were once impossible to achieve using traditional manufacturing methods. Fashion shows featuring 3D printed garments have gained attention, showcasing the fusion of technology and creativity in design.

4. Consumer Goods

It enables the creation of highly customized consumer products, including jewelry, furniture, and gadgets. Brands like Adidas and Nike are already experimenting with 3D printed shoes and apparel, offering customers a personalized experience. Similarly, jewelry designers are using 3D printing to create intricate designs with complex details that would be impossible with traditional methods.

5. Education and Research

It is playing a key role in education, allowing students and researchers to create prototypes, models, and hands-on learning materials. In research, 3D printing enables the rapid prototyping of new inventions, scientific instruments, and experimental models. Educational institutions are adopting 3D printing to encourage innovation, creativity, and STEM (Science, Technology, Engineering, and Mathematics) education.

Benefits (Additive Manufacturing) in 2025

- Customization: It enables the creation of tailored products that meet specific needs, whether it’s for a consumer, medical patient, or industry. Customization is not limited by traditional manufacturing constraints.

- Reduced Waste: Traditional manufacturing methods often result in significant material waste. With 3D printing, material is deposited only where needed, reducing waste and improving sustainability.

- Speed: It drastically reduces production times, particularly for prototypes and small-batch production runs. This is particularly beneficial for industries where time-to-market is critical.

- Complex Designs: It allows the creation of geometries and structures that would be difficult or impossible to achieve with traditional manufacturing methods, such as hollow parts, intricate lattices, and organic shapes.

- Cost Efficiency: For low-volume production runs, 3D printing can be more cost-effective than traditional methods, particularly when factoring in reduced material waste, tooling, and labor costs.

Challenges

While It holds immense potential, there are challenges that must be addressed:

- Material Limitations: Although a wide variety of materials are available for 3D printing, certain materials may not meet the required strength, flexibility, or durability for specific applications.

- Speed and Scalability: While 3D printing is great for prototyping and small-batch production, scaling up to mass production can still be time-consuming and costly.

- Intellectual Property Concerns: As 3D printing makes it easier to replicate designs, intellectual property theft and unauthorized reproductions are becoming a concern for companies and creators.

The Future

As technology continues to evolve, It is set to play an even greater role in transforming industries. In the future, we can expect to see innovations that allow for faster printing speeds, new materials, and greater design freedom. The combination of AI, robotics, and 3D printing will further streamline production and enable entirely new manufacturing paradigms, making it an essential tool for industries aiming to innovate and stay ahead in a competitive marketplace.

In conclusion, (additive manufacturing) is revolutionizing the way we design, create, and produce in 2025. With its ability to enable customization, reduce waste, and support complex designs, this technology is shaping a new era of manufacturing that promises to impact almost every sector, from healthcare to aerospace. As the technology continues to advance, the future of 3D printing is brighter than ever.